NEWS

Aurora Laser

Laser Repair Comprehensive Services

Time:

2025-04-03 15:19

Source:

Nanjing Aurora Laser Technology Co., Ltd. is an innovative enterprise specializing in the field of lasers. We have a professional technical team and first-hand laser sales resources. Our technical team has worked in various well-known laser companies at home and abroad, and has rich experience in laser fault diagnosis and maintenance.

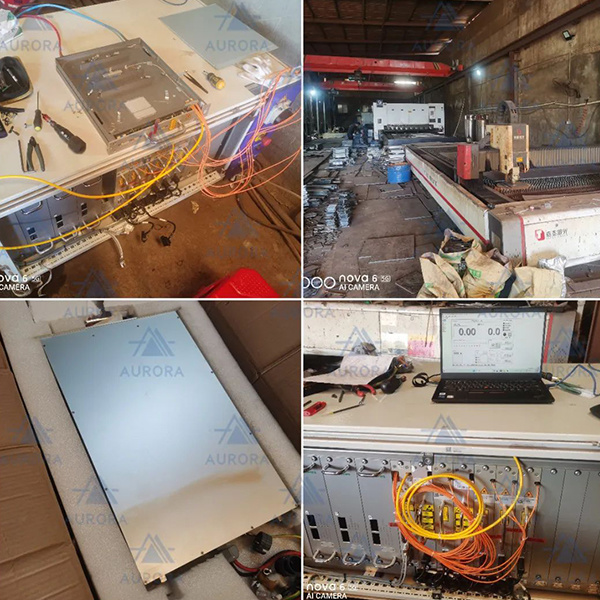

We always adhere to the service of "high efficiency, low cost", providing one-stop service for your business needs in laser applications. This issue has compiled a total of 20 latest maintenance cases, mainly including laser maintenance, fiber replacement, module replacement, module repair, cutting head maintenance, equipment relocation, and other cases.

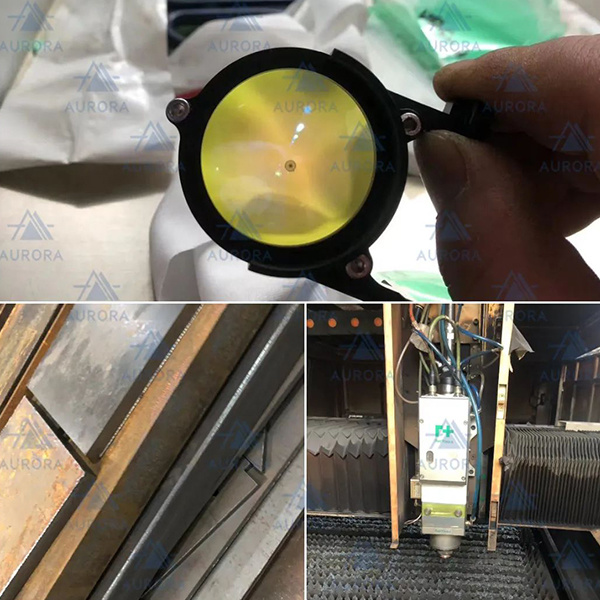

Repair Case 1

Bodor 6KW laser source. There are large black spots in the red light. Check the cutting head, replace the internal lens, and resume production.

Repair Case 2

2018 Quck laser cutting machine. There is a problem with the adjustment system. After on-site maintenance and debugging by the engineer, production has been restored

↓↓

Repair Case 3

Tianqi 1000W laser cutting machine. The fan of the IPG chiller does not turn, and after replacing the Hanli 3000W chiller, it returns to normal

Repair Case 4

jiatai laser cutting machine, using Reci 6000W laser source. Fiber optic crystal shattered, production resumed after replacing fiber optic.

↓↓

Repair Case 5

2020 3KW IPG laser source. Replace the fiber optic cable, replace the cutting head BM111 with a complete set of lenses

↓↓

Case 6

Tonkwi laser cutting machine, using 2016 IPG 1000W laser source.

The installation of the replacement Max laser has been completed and normal production has been restored after debugging.

↓↓

Case 7

Jiatai laser cutting machine, using IPG 6000W laser source.

The laser power is insufficient, and two internal modules were found to be damaged in the laser log. Two modules were replaced and the power was restored to full power

↓↓

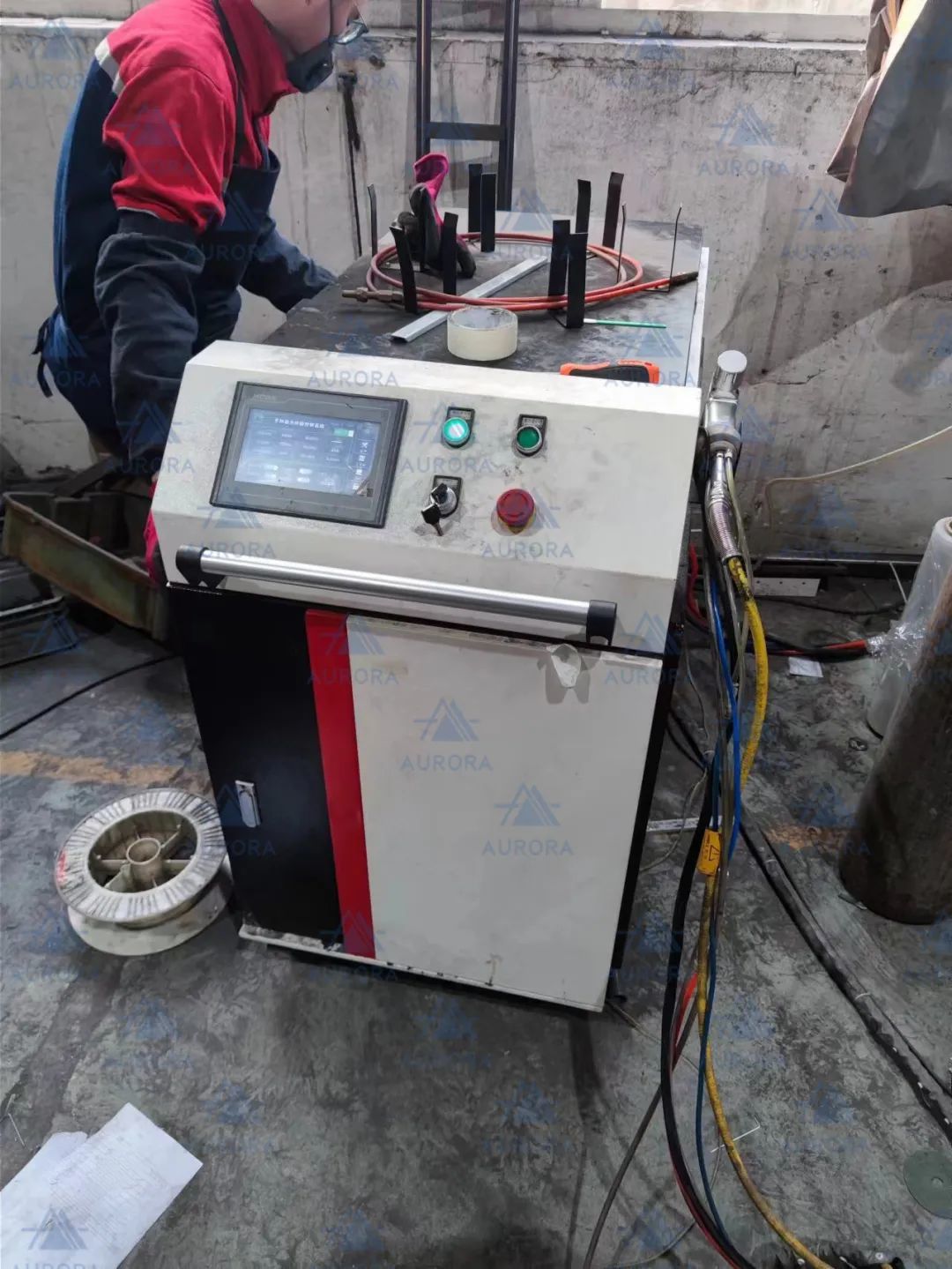

Case 8

Replacing lenses of laser welder, clean the waterway and restore normal operation.

↓↓

Case 9

Han's laser cutting machine, using IPG 1000W laser source

Replacing one laser modules, repairing two laser modules, restoring full power now

↓↓

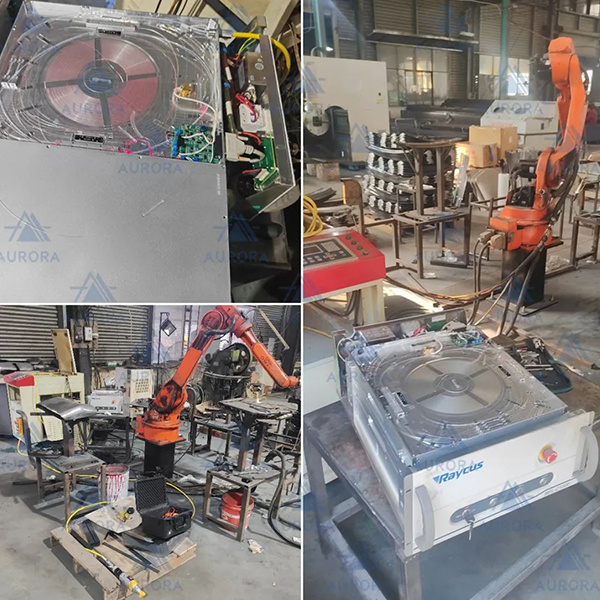

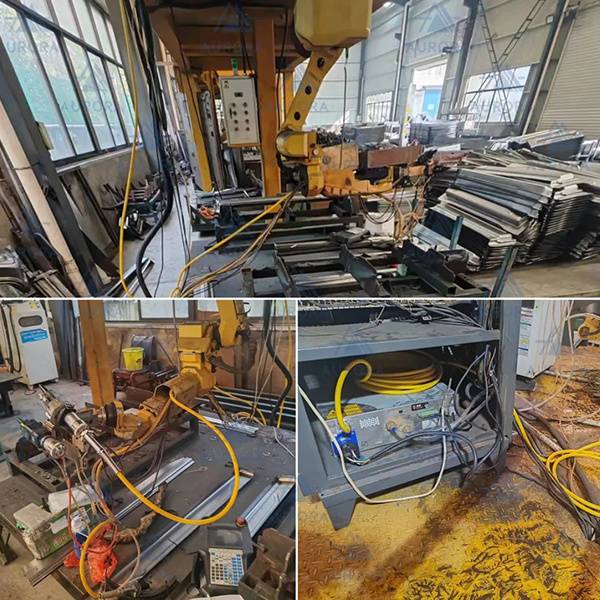

Case 10

1000W Raycus laser source, Robot cutting and fiber replacement completed

↓↓

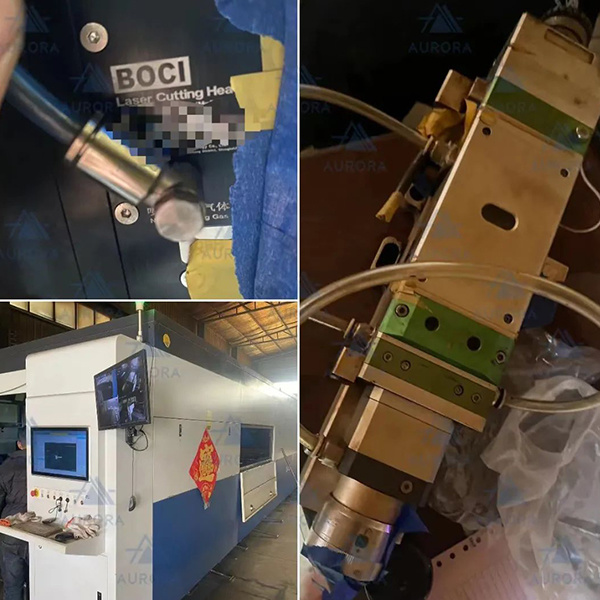

Case 11

Lead laser cutting machine, Raytools BM111 laser cutting head replaced into BOCI BTL421 cutting head, resume normal production

↓↓

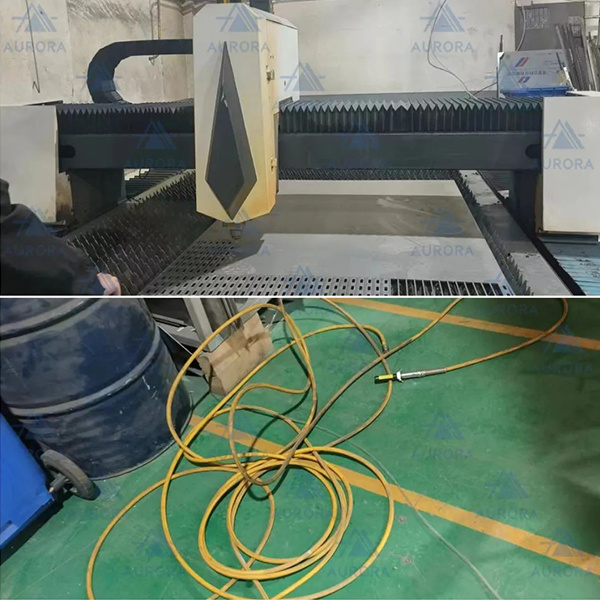

Case 12

2019 QUCK laser cutting machine, Beckhoff system, transforming 4000W Precitec cutting head into Raytools BM06K

↓↓

Case 13

Baiwei laser cutting machine, replacing 1500W Raycus laser source with 1500W Max laser source

↓↓

Case 14

1500W IPG laser source. The original fiber was burned, and cutting production was resumed after replacing the fiber

↓↓

Case 15

HSG laser cutting machine, using IPG 2000-U-K laser source. Circuit failure, on-site repair to restore production.

↓↓

Case 16

2015 IPG 3000W laser source, replacing laser fiber cable.

↓↓

Case 17

HSG 6020 cutting machine and Prima 6020 cutting machine.

Two devices have completed the move, and the workbench has been exchanged normally with normal light cutting.

↓↓

Case 18

2020 2KW IPG laser source.

The original optical fiber burned out, and production resumed after replacing the fiber.

↓↓

Case 19

4000W IPG laser source

Laser power attenuation, power restored after repairing module

↓↓

Case 20

HSG laser cutting machine, IPG-YLS-6000-K laser source.

Replacing laser modules, resume production.

↓↓

Nanjing Aurora Laser Technology Co., Ltd. is a technical enterprise providing domestic and foreign industrial laser technology consulting, maintenance services, laser welding machine application, laser cutting machine maintenance and laser spare parts sales.

Main Products: Laser Nozzles, Ceramics, Protective windows, Focusing and Collimating lens, Sensors, Cutting heads, Laser source, Water chillers, Laser Welding and Cutting Machine

Technical Advantages: With more than 10 years of maintenance and service experience in the laser field, the company has cooperated with many well-known enterprises, and has many experienced maintenance engineers, process engineers, installation and commissioning engineers, who can provide on-site service at any time to ensure the efficient operation of your equipment

Related News